Vapor Recovery Units

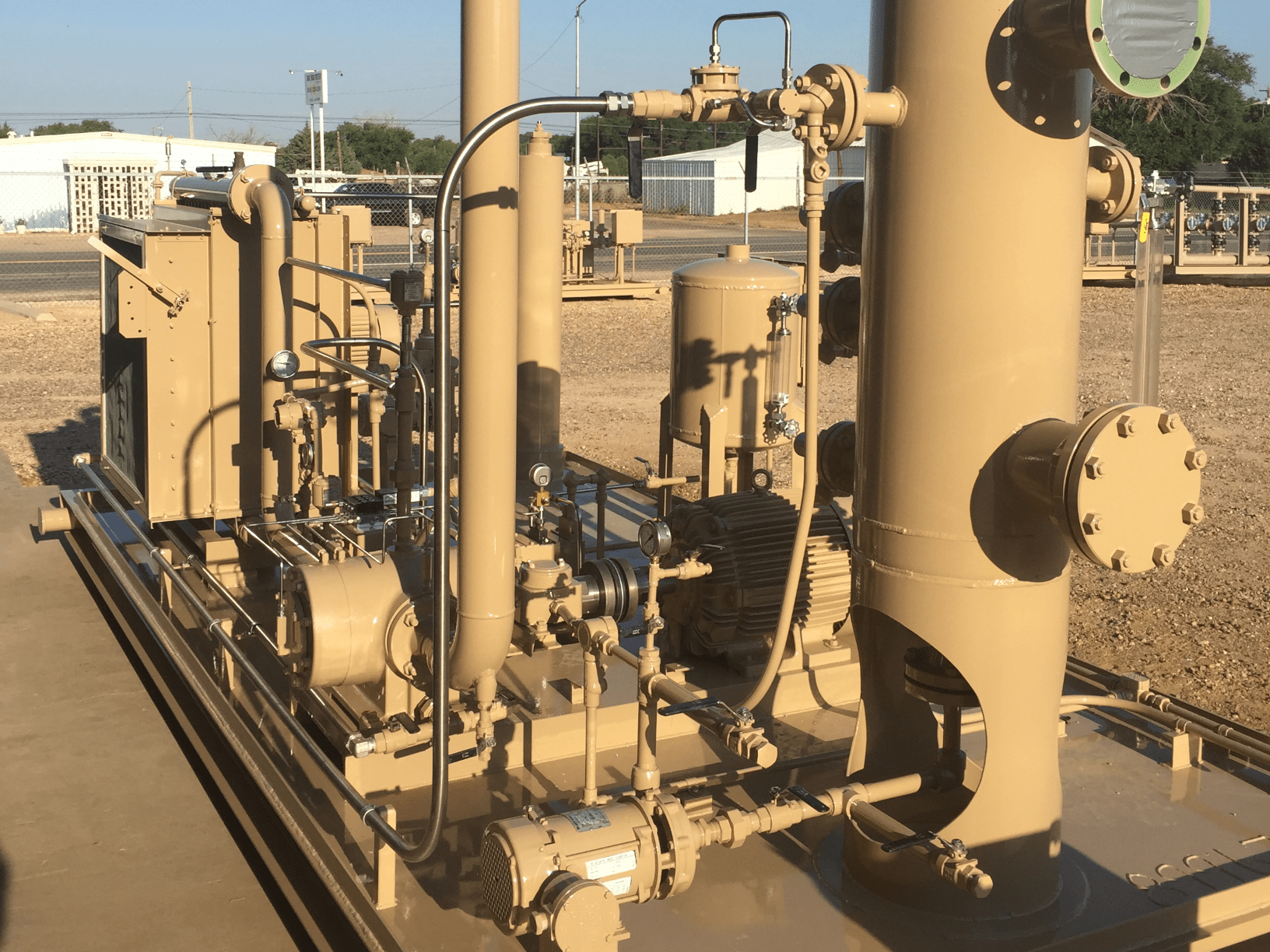

HMS packages various types of gas compressor packages based on gas volumes and pressures.

Vapor recovery is used in the chemical process industry to remove or recover vapors from storage tanks, usually because the vapors are harmful or valuable. Vapor recovery consists of a closed venting system from the tank to a vapor recovery unit, which will recover the vapors for either storage or send them to flare.

Vapor recovery units are also becoming commonly used in the oil and gas industry as a means of recovering natural gas vapor and making it a usable and profitable product. Hughes Meter and Supply packages three main types of RU compressor units:

- Blowers – The least expensive, used for various gas volumes at low discharge pressures: 15 psi discharge or less

- Sliding Vane – Cost varies, used for moving various gas volumes at medium discharge pressures: 20-80 psi discharge

pressure - Flooded Screw – Cost varies used for moving various gas volumes at medium to high discharge pressures: 20-350 psi discharge pressure

Units can be designed to run continuously slowing down or speeding up depending on the tank suction pressure with the use of a variable speed drive or direct drive single speed and recirculate via a discharge bypass valve.

To properly size a unit, we will need:

Specific gravity of the gas being compressed- Gas volume

- Line pressure for discharge

- Electric or gas engine drive